WEGU offers its customers the highest level of innovative solutions.

Vibration damping

When it comes to solving problems with vibration control and acoustics, WEGU GmbH Schwingungsdämpfung is recognized as a competent and reliable partner in the automotive industry.

We offer our customers the highest level of innovative solutions.

The products made here can be found in nearly all high-quality exhaust systems of reputable vehicle manufacturers. We meet the ever-increasing demands for comfort – especially in the acoustics area – with new and continuously updated products that guarantee our customers and us a technical and economic competitive edge.

Technological competence

WEGU GmbH Schwingungsdämpfung has the know-how to develop even complex parts as rubber-metal, rubber-fabric, rubber-plastic and silicone-metal composites under its own technical responsibility and can produce these with state-of-the-art, also automated production processes.

Product groups

- Exhaust hangers

- Exhaust dampers

- Gearbox and chassis stabilizers

- Bellows

Exhaust and gearbox dampers (vibration dampers)

The properties of most of our vibration dampers can now be quickly modified with a new and unique modular system without any costs arising from tooling changes. This system allows us to create a very flexible production process with a high degree of automation.

For our customers, this means high potential savings in tooling costs and component prices, thanks to this modular system and the associated production automation.

Exhaust hangers

Our newly developed pendulum systems for exhaust technology meet all technical requirements placed on modern, high-quality suspension elements.

A new design structure has made it possible to realize significantly more cost-effective suspension elements compared to solutions from competitors. All of these suspension elements are marked individually with specially developed machines. This guarantees optimum traceability.

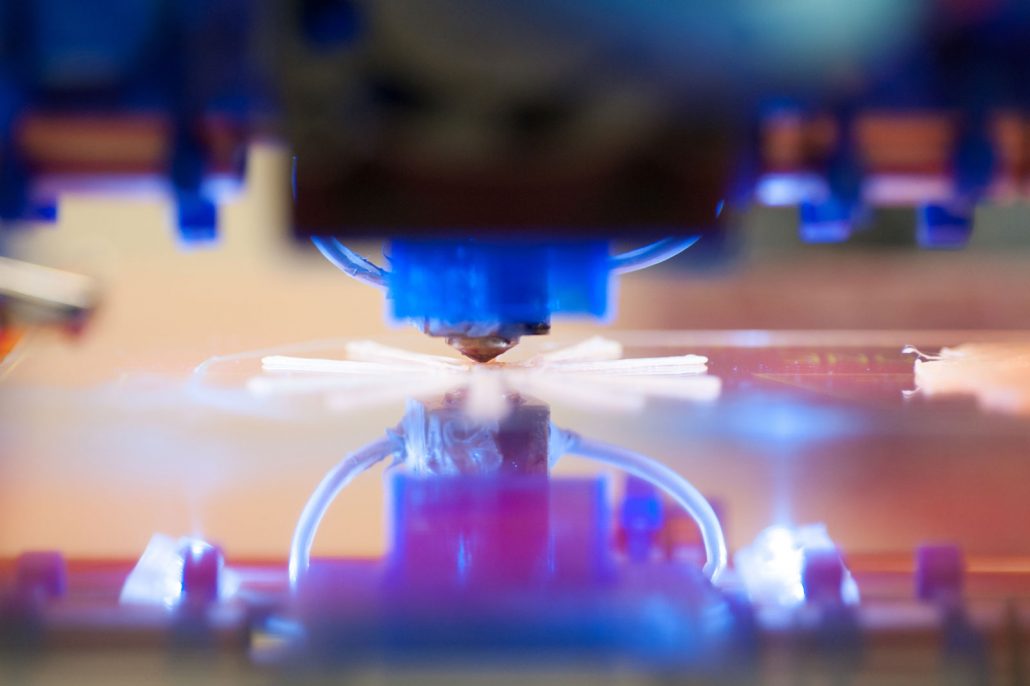

Machinery

With our modern machinery, we can realize innovative manufacturing processes which guarantee a technical and economic competitive edge for our customers and us.

Research & development

- Our technical center includes a large clamping field used for the structural and dynamic characterization of the components. Component strengths are tested and evaluated on single- or multi-axis test rigs.

- Two state-of-the-art electric shakers (with sinusoidal force peaks of 10 and 35 kN, respectively) make it possible to project service lives via customized PSD profiles and shock testing (abuse testing).

- All testing machines have climate chambers, enabling component characterizations from -30 to +200°C.

Lightweight systems

All competencies for plastics processing are available in the strategic Lightweight Systems business unit within the WEGU Group. Our project engineers, designers and process engineers master the constant challenges of developing innovative products and manufacturing processes.

Dedicated and qualified teams know the requirements and wishes of the automotive industry. Our strategic product groups regularly share information in daily communications with the development and purchasing departments of the leading manufacturers and their system suppliers.

With a versatile and modern injection molding production system at two manufacturing sites, with a high degree of automation in Germany and low wage levels in Slovakia, we can offer specific solutions as well as develop and manufacture innovative, cost-effective and high-quality products.

Technological competence

The strategic Lightweight Systems business unit sees its expertise in the optimized design of plastic parts through functional integration and in innovative multicomponent solutions (particularly multicomponent injection molding). Even for existing products, value analyses yield numerous approaches for cost reductions, for example through simplifications or intelligent tool concepts.

Injection molding machines for 1K, 2K and sandwich products with clamping forces ranging from 600 kN to 32,000 kN offer capacities for all component sizes required in the automotive sector.

The processes are highly automated or realized with qualified production personnel, depending on the product requirements.

These core activities are in line with the car manufacturers’ intentions to use higher proportions of plastic assemblies in future vehicles.

Product groups

- Engine compartment parts

- Steering bushings

- Fenders with spray mist reduction

- Plastic mud flaps

Machinery

Our modern machinery enables us to realize innovative manufacturing processes which guarantee a technical and economic competitive edge for our customers and us.

Research & Development

We use the latest Moldflow version for the design and layout of our products.

Test procedures and development services that we are unable to provide in-house are realized in close collaboration with appropriate university institutes.

At WEGU’s own technical center, dynamically stressed components in particular can be tested under numerous conditions. A dedicated laboratory can test all relevant material-specific properties and supports us in the development as well as series monitoring.